Polantis and BIM & More get together to revolutionise PIM

Polantis and BIM & More both have more than 10 years of experience in BIM and know how to support manufacturers in this development. Today, both companies get together to introduce a new PIM offer.

An innovative high added value PIM system

PIM (Product Information Management) is the process of gathering crucial data about a construction product or material. Every AEC manufacturer today has some level of PIM available.

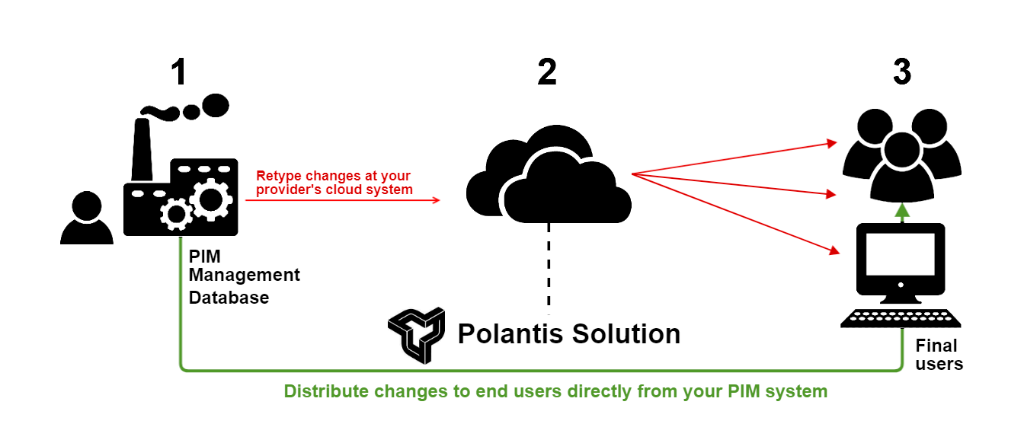

Thanks to the innovative PIM Single Source Data Managment devised by Polantis and BIM & More manufacturers can now transmit their product data to all their specifiers in real-time without re-typing data and with no buffers.

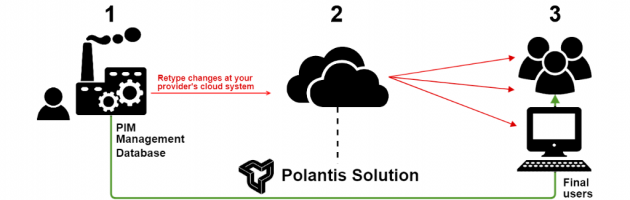

How does it work?

Itaï Cellier, architect and CEO of Polantis, explains: “Today, thanks to the collaboration between Polantis and BIM & More, all our customers can get a real ‘Single Source’ system: they can change their products’ data through their own database (whether it is dealt by the Polantis cloud or by the customers). Meanwhile this change appears for all the prescribers through their Polantis plug-in.”

Thus, the AEC manufacturer is assured that with a single clic he can update all of its specifiers of any change in properties, performances, classifications etc of any of its commercialised products. The data flow from manufacturer to end user is uninterrupted. No intermediary agents, no need to copy data into an external cloud service, no delays. Itaï Celliers adds: “To my knowledge, we’re the only ones to propose such extensive PIM solution”

This new offer has a high importance, ensure that BIM models will constantly be up to date with the latest version of data coming directly from the manufacturers. The era of errors, omissions and outdated data on BIM models has come to an end.

Matthias Uhl, CEO and founder of BIM&More adds: “The natural cooperation between Polantis and BIM & More represents a huge improvement for our clients: A truly single-sourced BIM data management – Extremely time and cost efficient and above all – knowing that your objects are always up to date on your specifiers workstations.

This new breed of powerful BIM data management opens new horizons for AEC manufacturers and gives them a great competitive edge”

To get to know more about BIM & More, click right here.

We suggest you the following articles:

- Trespa’s CAD and BIM catalog modeled by Polantis

- Manufacturer’s Thursday #9 with Rakif Remal

- 2018 BIM Contest Team Standing

Am I ‘BIM ready’?

BIM D-Day Looms

Unless you’ve been living under a rock for the past two years, the chances are you know about the impending government BIM reform. Numerous articles have been written about what BIM is, how it can save everyone in the construction chain money and ultimately how those that don’t adapt will be left behind. The deadline looms and is now less than 2 years away.

Scaremongering is rife but what is lacking is practical and sound advice on how to proceed as an AEC manufacturer. You have questions that need to be answered: How do I invest in BIM? Do I need to train my staff in BIM? What kind of return on investment am I looking at? How long will it take? Can I create BIM versions of my products by myself?

BIM adoption – far from uniform

So where are you in the global race to adopt BIM? Well, most accept BIM is the way forward for the construction industry, but there exist vast cultural differences when it comes to the uptake of the technology. Early adopters in the US and parts of Europe are already reporting a significant return on investment for BIM.

Some are being forced to change by law, as in the UK. This list also includes the Netherlands, Denmark, Finland and Norway – all of which will require the use of BIM on publicly-funded building projects by 2016.

Others are being encouraged more ‘gently’. The European Parliament recently voted to « encourage all European countries to recommend the use of electronic tools, including BIM, on public works contracts. »

As usual, Asia is steaming ahead. One UK construction expert recently lamented that « In Japan, modular construction is used on more than 50% of its buildings, while the UK uses it in less than five per cent. »

Who needs to know what about BIM?

When it comes to BIM uptake though, the real disparity is not geographical, it is between the actors involved in the construction chain. That’s somewhat ironic as the whole point of BIM is to enable manufacturers, architects, quantity surveyors, engineers, builders and owners to better communicate. By 2016, we are told, if any of these groups want to have a hand in lucrative public projects, they will all need to have a firm grasp of what BIM is and how to use it. BIM is no different to any other new technology in that some are more willing and able to get on board than others.

So here’s the good news for you as an AEC manufacturer. This really isn’t your problem because of all the actors in the chain, you have the most simple part to play in the whole reform process. All you need to do is to provide a BIM version or catalog of your products. This is not only simple, you are the group most likely to see a return on investment. Why? well, a BIM catalog will help you to promote and sell your products to the very people that prescribe them.

What’s the next step?

So you’ve accepted BIM is the way forward and you’ve decided to go ahead and create a BIM objects catalog. You now have two options, outsource the process to a CAD and BIM objects expert manufacturer or attempt to create your catalog yourself. Whichever option you choose, don’t forget that albeit the fact that more and more specifiers and AEC professionals use BIM. A BIM method is only mandatory in the public market. If 39% of architects knew about or were already using BIM in the UK in 2013 (according to the NBS) – this also means that the remaining 61% don’t use it yet. The US, which is a « ripe BIM market » had 60% of architects using BIM according to Autodesk’s report if this is what we can expect in 2016’s UK it still means that a big chunk of AEC professionals will never be BIM ready or at least will be extreme laggers. These architects and specifiers will continue using « traditional CAD » indefinitely and you, as an AEC manufacturer cannot allow yourself to ignore them. Make sure you’re not only BIM ready then. Make sure no matter which professionals using no matter which solution or method – has access to your catalogs.

Vmzinc BIM catalogue created by Polantis

First part of the Vmzinc BIM catalog is published by Polantis

Vmzinc, the specialist in innovative zinc solutions for building covering published its first fifty Rendering and BIM textures compatible with 100% of professional software used by architects and AEC professionals.

This first VMzinc BIM catalog is part of the company’s communication strategy and its group: Umicore – an international specialist in metals and materials technology. VMzinc is its international brand name of rolled zinc solutions for the building industry.

VMzinc manufactures a broad range of products for the building industry, including a full range of Titanium-Zinc products available as sheets, coils or as specially tailored systems. Their extensive range of products reflects their wealth of professional and practical experience. These products are designed to meet needs of various climates and standards worldwide.

The first 50 BIM objects for VMzinc were specially designed by Polantis so that they could seamlessly fit and integrate into any kind of building project. The product categories « Systems and and products for roofing » and « Systems and products for façades » were conceived first in order to reply for the increasing demand of architects, specifiers and other AEC professionals. The other product categories are already under production by Polantis’ expert architects and will be published during 2014.

VMzinc hopes to profit from the ongoing BIM revolution and make sure architects and specifiers in the UK and elsewhere in the world could employ their range of products easily into their projects. The VMzinc catalog joins hundreds of other CAD and BIM objects catalogs recently published by a many AEC manufacturers in anticipation for the extensive UK BIM reform that will be in full effect on the 1st of January 2016.

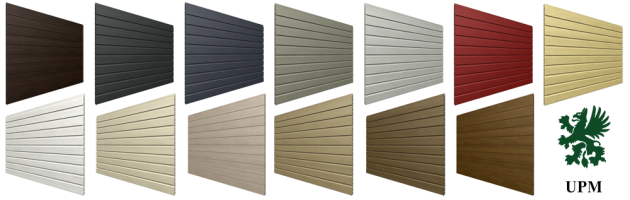

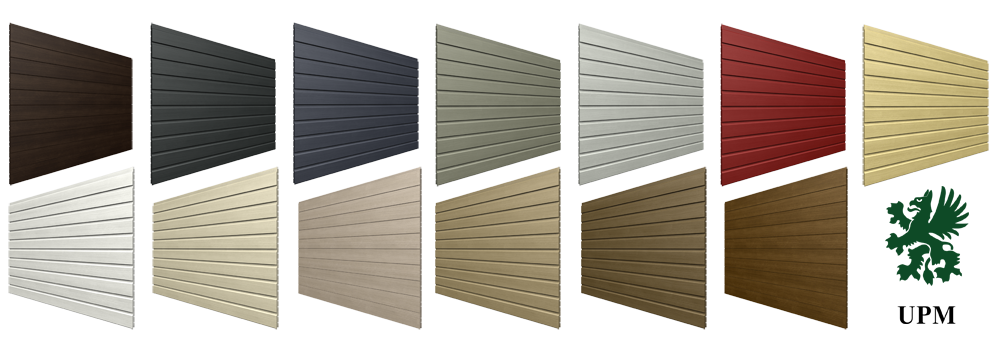

Publication of a CAD and BIM Catalogue for UPM

The first CAD and BIM catalog for UPM was published today by Polantis. The Finnish manufacturer, a leader of its market – enters the BIM era.

UPM the Finnish giant of wood for construction enters the BIM era with the publication of a first CAD and BIM objects catalog made available for Architects and other specifiers in the UK and the rest of the world online at polantis.com

The first products to be published are systems of wood panels for cladding. UPM chose to make them available in 16 different CAD, BIM and Rendering formats. The BIM components could be easily integrated into a 3D BIM model and enrich any project with an extended palette of colors and motives.

UPM is a frontrunner of the new forest industry. The company leads the integration of bio and forest industries into a new, sustainable and innovation-driven future. UPM is known to create value from renewable and recyclable materials.

UPM’s structure consists of the following business areas: UPM Biorefining, UPM Energy, UPM Raflatac, UPM Paper Asia, UPM Paper ENA (Europe and North America) and UPM Plywood.

In 2012, UPM’s sales exceed 10 billion euros. They are present in 65 countries and their production plants exist in 15 different countries. UPM employs over 22,000 people worldwide and their shares are listed on the NASDAQ OMX Helsinki stock exchange.

Making a CAD and BIM catalogue in house

Making a CAD and BIM catalogue in house can be costly. Here are a few questions you should ask yourself before embarking on such a project:

Sometimes it is best to find an alternative rather than fight against all odds…

1. Do you have the right team to create a CAD and BIM catalogue in house?

It’s likely you have a team of technical experts at the heart of your business. This team is probably made up of experienced engineers who design and process your products. The question is do they have the specific skills necessary to develop a professional CAD and BIM catalogue in house?

Most product and industrial engineers are well versed in PLM computer design but are not architects. None of them have previously worked in architectural firms or specified products in an architectural design. Only an architect can create a high quality, professional CAD and BIM catalogue because only an architect has the specific experience in BIM or CAD software and the understanding of the proper functioning of an architectural practice.

2. Do you have the required software licenses to create your CAD and BIM catalogue in house?

A professional CAD and BIM catalogue needs to make your objects available in as many formats as possible. In order to maximise your return on investment, architects and prescribers must be able to download and manipulate the 3D versions of your products in to the software they habitually use. Today there are four BIM software versions in use as well as dozens of CAD and rendering programs.

Converting objects between one BIM program and another is quite simply impossible (this despite the claims of IFC and IFD’s so called « interoperability »). Converting CAD objects from one format to another is possible(in most cases) but it can be tricky.

The upshot is, if you fail to produce your catalogue in the maximum number of formats (at least 10) you will be limiting your business to a very small number of architects and prescribers. (i.e only those who use the few programs your objects are available in)

3. How long would it take your employees to master the software necessary to create a CAD and BIM catalogue in house?

CAD architectural programs, and to a greater extent BIM programs, are far removed from the programs used by your designers and engineers. They really are distant cousins and converting an object from PLM to CAD (for example from .igs format to .dwg format) will more often than not produce monstrously large files with too much detail, in the wrong scale and may contain sensitive information you don’t want out of your premisses.

Converting an object from a PLM format to a BIM format is simply impossible today. (.sat to .gsm for example) Even if you manage somehow to make a « geometrical conversion » of a PLM object into a BIM format (i.e – you manage to convert the 3D form from one software format to the other) – you will end up with a heavy « dummy » object that has none of the attributes and parameters necessary for a proper functioning in a BIM project environment.

If you want to create your CAD and BIM catalogue in house, you will need to think about acquiring a number of BIM and CAD software programs. Consult our cost analysis below for more detail.

4. Have you really considered the workload associated with creating a CAD and BIM catalogue in house?

Creating a 3D catalogue can be immensely time consuming without the aid of technologies specially adapted to the task. Even if you do manage to hire top notch architects, they will still have to spend time mastering the programs they’re not familiar with. Once they do, they will then have to learn how to create an object using this software. After all, these programs are designed for the purpose of architectural design, not creating objects for catalogues.

Your architects will need to learn how to ‘divert’ or ‘hack’ to properly create your objects. A lot of these programs come with a ‘catalogue object creation mode’ but its rare to find someone with the know how in this domaine because very few architects pass their time creating catalogue objects.

At the bottom of this article you’ll see how it will take two excellent architects 19 years to create 1000 catalogue objects in all the necessary formats – don’t underestimate the time it takes!

5. How do you intend to distribute and promote your CAD and BIM catalogue once it’s finished?

Creating a CAD and BIM catalogue is good, but getting it to the people who will use it is even better. If you have managed to create a professional catalogue you will now have thousands of files, some in 2D format, some in 3D, others in BIM. Some will be purely textures or ‘shaders’ that can cover polygonal surfaces etc. How do you intend to get all of this out to architects and prescribers? Remember, each uses a different software program and perhaps different methods within a program.

-If you wish to distribute these files online, you will need to think about a costly web upgrade for your site. Aside from the distribution you’ll have to think about costs associated with hosting and downloading these objects.

– If you’re thinking about sending your catalogue via email, how will you go about managing a group of files that might totalize 8Go and how will you ensure your mail isn’t flagged as spam? Do you have a good list of contacts when it comes to architects and designers?

-If you want to hand out copies of your catalogue at trade fairs and other events which is the best format? A QR code? A DVD? a USB key? All of these need to be properly designed and thought of.

Time/Cost Analysis

Let’s imagine you produce a range of 1000 different products and you want to create a CAO/BIM catalogue

– You will need to find and hire the services of two experienced architects who are content to abandon their career in architecture in favor of designing catalogue objects (no mean feat!) Assuming you manage to negotiate a salary of £2500 for each per month, you’re looking at an annual cost of : £60,000

– You’ll need to buy software licenses for CAD and BIM for 2 desks + any other essential software (Adobe creative suite, pack office, etc) That’s 12 software packages X 2 at an average cost of £3700 per license = £88,800

– An architect who can master several CAD and BIM software is a rare thing. You will need to pay for training. It takes around 5 days to properly master each program at an acceptable level. On top of that each architect will need to learn how to use the object creation mode of each software package. A day’s training costs around £250. £250 X 5 days for each program X 10 programs = £12,500

– 2 workstations properly adapted to high level 3D creation = £5000

The time it takes to create a professional CAO/BIM catalogue will also have an impact on costs… There are about 230 working days in a year (52 weeks X 5 days a week less 30 days of vacations / sick leave / bank holidays etc)

The time it will take to train your two architects will end up at around 50 work days. Add to that around 30 days each to learn how to use the object creation mode in each program. So each architect will need 150 days of training in the first year.

A very good architect who is also an expert in CAD and BIM will create, on average, one complex object per day. In just one format. Remember, you need to create objects in 10 – 15 formats. So let’s imagine your architects are particularly efficient and they manage to produce all the formats for one object in 10 days. At the end of the first year you will have 30 finished objects for your catalogue.

So the first year’s cost: 60,000 + 88,000 + 12,500 + 5,000 = £165,500

That’s £5,500 per object

The second year will cost the architect’s salaries + the software updates. Let’s assume your architects produce around 50 complete objects in all of the required formates each year. You will be looking at a cost of about £2,600 per object.

In Conclusion:

It will take your firm around 19 years and cost you more than £2,6 million to create a professional CAD and BIM catalogue in house covering your range of 1000 objects. That’s with two architects. If you hire 4, you will of course halve the time and double the costs. If you hire 6 architects and a project manager, they could get the time down to around 3 years but that will cost you significantly more.

Creating a CAD and BIM catalogue in house at the cost of around £5000 per object probably isn’t a very good idea, especially when a cheaper, easier alternative exists.

The alternative:

Get a professional CAD and BIM objects manufacturer to work on your catalogue. A good service provider and an expert in CAD and BIM catalogue creation will:

- Get the same work done 80 and 95% cheaper than the cost of creating a catalogue in house

- Provide you with 1,000 objects within between 6 and 8 months

- Ensure your catalogue is distributed to prescribers via your website and via its platform

- Offer technical support to your architects and prescribers

If you have any questions, feel free to drop them in to our comments box

BIM – Definition – What is BIM?

BIM or « Building Information Modeling » has so many definitions it is almost ridiculous. Some don’t even define BIM as « Building Information Modeling » but rather as « Building Information Model » or « Building Information Management ». Many organizations, software editors and individuals claim to be the « true inventors » or « true initiators » of BIM. Some insist they were the first to know about BIM and know best how to use it.

So what is BIM ?

God forbid, if you seek the answer in Wikipedia, you’ll most probably regret it. It fails to explain this multi-faceted and vast concept and settles for a bland, general and vague definition of what BIM is.

Luckily, BIM is actually something quite simple to grasp if you’re an AEC manufacturer. Most existing BIM ‘explainers’ are directed at architects or at the clients of building projects. In this post however, I’m going to explain what BIM is from the AEC manufacturer’s point of view.

The easiest way to quickly grasp what BIM is, is to first understand what a BIM object is and then understand what this kind of object is good for, and the best way to understand it is:

A BIM object functions as a recipient

And here’s a picture of a glass of water to help you remember it:

The glass itself represents a 3D model or any other kind of what is commonly called « Geometry » which basically means a 2D or 3D shape of SOMETHING

The water inside it represents INFORMATION ABOUT THE SOMETHING

And as you can see, the « water » adopts the shape of the object it is contained in. That is it. Simply put, a BIM object is a 3D geometry that contains information about it’s essence.

Now, if you are an AEC manufacturer all you have to do is imagine one of your products instead of the glass of water shown above. Your product could obviously be described geometrically (i.e – modeled in 3D) and you could probably also say lots of things about that product of yours. Let’s imagine for the sake of the example that your product is an automatic door instead of that glass:

This door has a certain shape, a width, a length, a thickness and several parts – this is its GEOMETRY.

It probably comes in different sizes and proportions to fit different types of openings – this is PARAMETRICAL information.

It also has different materials, (wood, metal, rubber, trans-lucid or transparent glass, plastic etc.) It replies to some norms and standards and is classified under a certain reference or catalog number. It is also manufactured by someone (you) and you have a phone number and an address where you (or your sales / technical force) can be reached. All of this is essential information.

If this automatic door is a BIM object then all of this information (parametric or not) is simply INTEGRATED into the geometry of the 3D object.

You probably understand by now what all of this is good for. The ability to integrate information into a parametric 3D object is a great thing. It allows the architects and any other AEC professionals (quantity surveyors, engineers…) involved in the conception of a building – to conceive a building with hundreds of such intelligent « building blocks ». Each block is « self aware » of what it is and each interacts with all the other elements of said building. For example, this door integrates into a wall somewhere in the project. The wall itself contains information about its thickness, it’s function (supporting or just separation of spaces) insulation, the dimensions of its openings etc. The wall might be « sitting » on a concrete slab covered with tiles of a certain shape and color etc etc. All of these BIM components together make a BIM MODEL and this intelligent BIM model is the basis to what BIM is all about.

Because, as soon as you have a BIM model, you can do many things. First, YOU CAN EDIT it really easily. For example, if you have a staircase in between two concrete slabs and you decide that you want the room’s ceiling to be higher all you have to do is increase the distance between those two slabs of yours, the staircase will respond automatically as it « knows » that it is connecting two floors and the BIM object that is this staircase will add extra stairs to itself and an extra length of railing to go along with it.

Second, this magical BIM model can provide you with tons of useful information that YOU CAN QUERY with a few clicks. In most BIM software you can get a detailed listing or nomenclature about all of the components that make your building. Not only how many square meters or yards it has but also how many doors, windows, chairs, and lamps it contains. This of course is very helpful if you’re an architect or a client.

If you are the person in charge of the maintenance of the building that is going to be built you could easily know how many pots of painting you’d have to purchase and when to refurbish it etc. A good BIM model will ensure EASY MAINTENANCE.

a BIM model is good for many other things as well, an engineer could use the model to make sure there are NO CLASHES that could occur during construction (For example: Part of the underground parking is built where a city sewage pipe passes or an air conditioning tube that goes right through where an electric installation is supposed to be)

This, in sum is all you, as an AEC Manufacturer need to know about BIM. Building information modeling is just that – a method that allows the entire supply chain of a building to better communicate with each other and access information about the thing they build when they need it. It makes life easier on everyone from the architect to the client and it all starts with a little BIM object that you provide the architect. This little BIM object is by far your best salesman as it tells your story, it showcases your competence and you wealth of knowledge and ingenuity.

How to sell to architects (Part 2)

If you wish to sell to architects you should probably first know a little about their work flow and when is the right time to approach them and offer your services or products.

What is it that they do?

“Now regard this pure white sheet of paper! It is ready for recording the logic of the plan. T-square, triangle, scale – seductive invitation lying upon the spotless surface. Temptation!

“Boy! Go tell Black Kelly to make a blaze there in the work-room fireplace! Ask Brown Sadie if it’s too late to have Baked Bermudas for supper! Then go ask your Mother – I shall hear her in here – To play something – Bach prefered, or Beethoven if she prefers.”

Now comes to brood – to suffer doubt, hesitate yet burn with eagerness. To test bearings and prove ground already assumed by putting all together in definite scale on paper. Preferably small scale study at first. then larger. Finally still larger scale detail studies of parts.”

Frank Lloyd Wright – An Autobiography – P. 156 – (Published – 1932)

Replace the T-Square, triangle and scale by CAD software, telemeter and a digital camera and you pretty much have the same methods today. Practicing architecture is all about proportions and scales, Architects start with an idea, a concept and they just keep on “zooming in” until the full picture comes to full effect in their imagination and of course, on their plans.

There are many methods, concepts, and “schools” to CREATE architecture, but what remains almost the same is that “coming and going” process; those constant cycles of analysis and synthesis. That, and the very final outcome: A universally readable drawing with strict rules – the execution plan.

How exactly do they do it?

Here are the most common phases of architectural work:

1. Getting and analyzing the program. After the contract between an architect and its client is established the architect takes the time to carefully study the program allocated. If it’s a public building, the program is usually crafted by specially trained architects and engineers providing a huge amount of norms, technical sheets and regulations to follow. In other cases, the architect builds the program along with his clients (for smaller projects usually, like private houses, cult facilities etc.)

2. First draft: 1/500 – 1/200 scale. Once the program is well defined and known to the designing team, the first drafting starts. Now methods vary: Some architects “attack” the 2D plans, sections and elevations that in due time will be transformed into the final execution plans and some start with 3D construction of volumes that will gradually become the spaces and shapes of the built project. In this very early stage, few architects turn to go over manufacturers catalogs.

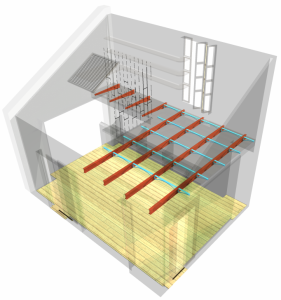

3. First validation by client: 1/200 – 1/100 scale. This is where things start to “get hot”… The first validation of a project’s design is always a bit stressful for the designing team. This is where the architect needs to “re-seduce” the client in some sort. In most architecture practices, this is done with plain, traditional 2D plans sections and elevations and… lots of verbal explanations. Then there are those who are more “technique savvy” – In order to make sure the client properly understands the project they use computer generated imagery like this:

CGI of a mezzanine

CGI of a mezzanine

(click to enlarge)

Axonometric X-Ray constructive analysis of the same mezzanine

Axonometric X-Ray constructive analysis of the same mezzanine

(click to enlarge)

Over the past few years, we’ve been witnessing a genuine increase both in the performance of 3D CAD software and in the skill and talent of young architects. Computer generated imagery is becoming more and more abundant in today’s architectural design market. This is also partly due to the fact that clients tend to demand this kind of high-end service more frequently. Those images could be easily sent by email to friends and family for them to give their opinion.

4. Second client validation and construction permit: 1/100 – 1/50 scale. No architect dares to hope that his client will be 100% satisfied with his initial design. Often, there are many modifications and changes, but the path is clearer and the team is reassured once the concept has been accepted. Now is the time to get “down to business” The design team’s work now, is to get the project approved by the authorities for construction. In most western countries, the construction permit drawings are handed in 1/50 scale with an “in-site” integration of the building (CGI again…) Like the following example:

In site CGI insertion (click to enlarge)

In site CGI insertion (click to enlarge)

Although in the first client validation phase, CGI is not mandatory, most competent authorities demand one, so that they could make an idea of the project’s integration impact on its surrounding environment.

5. Execution plans: Detailed 1/50 scale and some parts in 1/20 or 1/10. Finally! The project was approved by both client and the authorities now comes the final part of architectural designing where “all hell breaks loose” – This is usually where our poor design team discovers that the plumbing doesn’t perfectly fit with the foundations and that the window they chose for the hallway is no longer manufactured because the draftsman used an outdated catalog from 1988… The plans are sent back and forth to the contractors and engineers for review and there is much rejoicing. It’s during this phase that most of the materials and architectural elements are specified. In some places, plans are not enough and architects actually write down – for every room and corridor – a full detailed textual description of all of the amounts and materials. At this point, the client tends to develop nostalgic feelings towards his initial budget and the days his local bank manager actually smiled at him…

6. Construction. Oh dear, now we actually have to build all that??

IMPORTANT NOTE: These 6 phases are generalized. There are lots of variations. The process I described fits the description of building for a private client. Building for governmental or other institutions is somewhat different than the described above. I’ll be happy to detail it in the comments or future posts if there’ll be a demand.

Where do YOU come in?

Well, it depends on what you are manufacturing:

- If it is software for architects you probably want to find a time somewhere before phase 3 and after phase 5 – Architects will be much more receptive to new technologies when they are not on a tight deadline.

- If it is design furniture, your golden hour is during phase 2 when the architect aims to seduce his client.

- If you’re a manufacturer of doors, windows, flooring, or any other Parametric BIM object – It’s probably best to intervene during the 5th phase. Actually, if architects know of you – they’re most likely to contact you themselves.

Usually, architects work on several projects at the same time, and their phases do not overlap, how can you make sure you are reaching the designing team at the appropriate moment? Who should be your contact person? How do you find him or her? – All that and much more – in the following chapters.

How to sell to architects – Part 1 – Introduction

In the following series of posts, I’ll be reviewing the most efficient techniques to sell to and “sell through” architects.

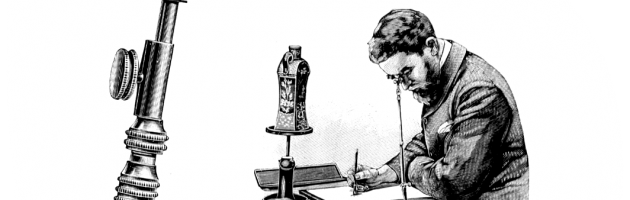

Architect at work from « Catalogue modèle de l’architecte 1913 » (Paris, France)

Why sell to architects?

According to our estimations, there are about 1.3 million active architects working in the building industry at any given time. Worldwide. You can safely double that figure if you want to include interior architects, decorators, office space planners, booth builders and other design related professionals. Those are key actors holding a “few” dozen billion dollar market.

Architects are decision makers. They are specifiers of building related goods as doctors prescribe medicine. And while pharmaceutical companies understood the later long time ago, most of the building related manufacturers didn’t seem to quite “get it” about architects. Yet.

The main reason behind that lack of comprehension is probably due to a profound misunderstanding of the architect’s work and role as a “prescriber of goods”. Here are, briefly, some points to take into account:

- Most architects don’t care much which chair or window they’ll prescribe within a similar budgetary limit or need. For example, if an architect gets to chose between a skylight window manufactured by company A and a similar product by company B (similar in general aspect, size and price) he or she will most likely choose arbitrarily the first one to “fall into their hands”. The reason for that is – time. The lack of – to be precise.

- Most of today’s architects don’t keep a well referenced, well-organized materials and product library at their offices. They get your beautiful well designed glossy and heavy catalog by UPS or your country’s postal service and just stack it somewhere in the darkest corner of their practice. The reason for that is, well, time.

- Most of today’s catalogs made by manufacturers don’t suit architects needs. Catalogs without measurements, catalogs in which the object is in a non-neutral context (ex: an armchair pictured in a hotel’s lobby) – The architect needs to do the mental exercise of extracting the object off the current context and imagining it inside his own design… To cite two of the most common problems of paper catalogs.

- 99% of today’s architects use at least one kind of CAD or BIM software. Making paper catalogs quite frustrating to them while making 3CT quite appealing.

- Specifying is a mere small fraction in the work process of an architect. In fact, only big architectural firms have real dedicated specifying teams. Most architecture firms are 5-10 employees strong and specifying is left to the very end of the design process.

- Most architects have few “fetish” objects they specify every time. As it’s very hard and sometimes even impossible for architects to keep up-to-date with all of the new products.

So how can you overcome all those points and how can you make sure you understand the relevant needs and related technology? In the upcoming posts, it will provide you with a complete overview, set of rules and guidance so you could start working and selling to architects in no time. Stay tuned.

Derniers posts

- L’utilisation d’outils digitaux, la nouvelle normalité dans le secteur de la construction 27 novembre 2020

- Agenda : Jeudi Prescription LIVE avec Annalisa de Maestri, le 22 octobre à 9h00 12 octobre 2020

- Paroles BIM ALTO PRODUCTION : le BIM ouvre des opportunités 8 septembre 2020

- Jeudi Prescription en ligne animé par Vincent Martin de BSolutions 8 septembre 2020

- Jeudi Prescription – Francesco Ciurleo, Architecte – BIM Manager Quadri Fiore Architecture 3 mars 2020

Search

Derniers articles sur le blog

- L’utilisation d’outils digitaux, la nouvelle normalité dans le secteur de la construction

- Agenda : Jeudi Prescription LIVE avec Annalisa de Maestri, le 22 octobre à 9h00

- Paroles BIM ALTO PRODUCTION : le BIM ouvre des opportunités

- Jeudi Prescription en ligne animé par Vincent Martin de BSolutions

- Jeudi Prescription – Francesco Ciurleo, Architecte – BIM Manager Quadri Fiore Architecture

- Jeudi Prescription BIMobject – Polantis animé par Téri Feugeas, consultante BIM architecte.

- Les objets BIM de FERPLAY modélisés par Polantis

- Apéro Prescription BIMobject – Polantis animé par Damien Cordier, architecte associé chez DRLW architectes.

- Témoignage du 2ème prix du Concours BIM 2019

- Témoignage du 1er prix du Concours BIM 2019